My 3D-Printed CO2-Powered Racecar Goes 23mph

| Timeline: | Spring 2013 | |

| School: | School of Engineering & Biomedical Science (SEBS) | |

| Course: | CADD 4 (Senior Year) | |

| Software Used: | Autodesk Inventor | |

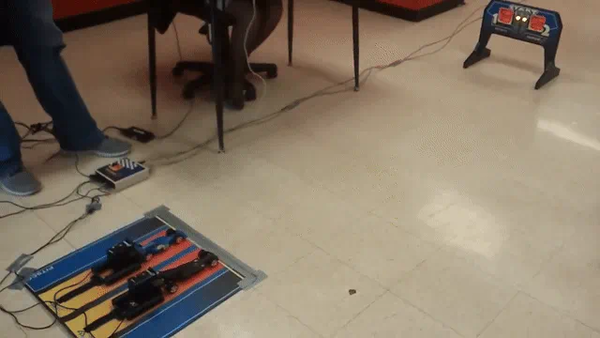

| Race Distance: | 5 feet | |

| Race Time: | 0.15 seconds | |

| Top Speed: | 33.3 ft/s (≈22.7 mph) |

Watch the Race Video

If a picture is worth a thousand words, a video is worth at least a million. Check out the race video to see my car in action.

The Origin Story: Star Wars Meets F1 (in High School)

Copyright Disclaimer

All trademarks are properties of their respective owners.

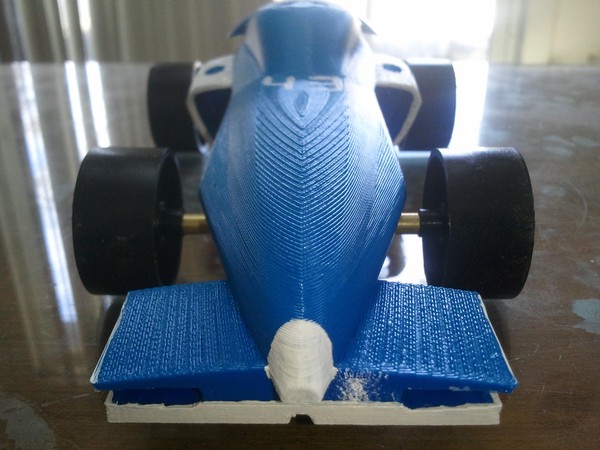

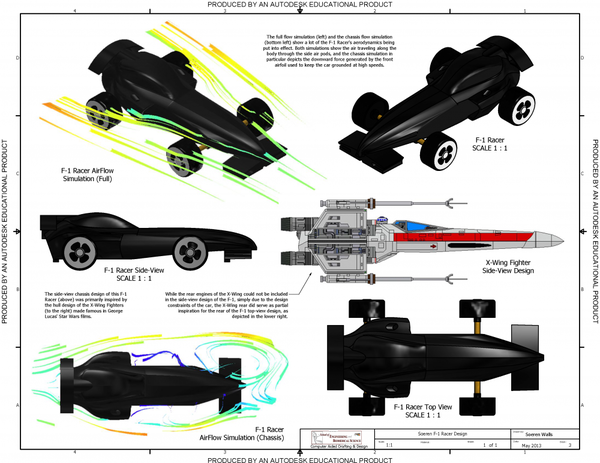

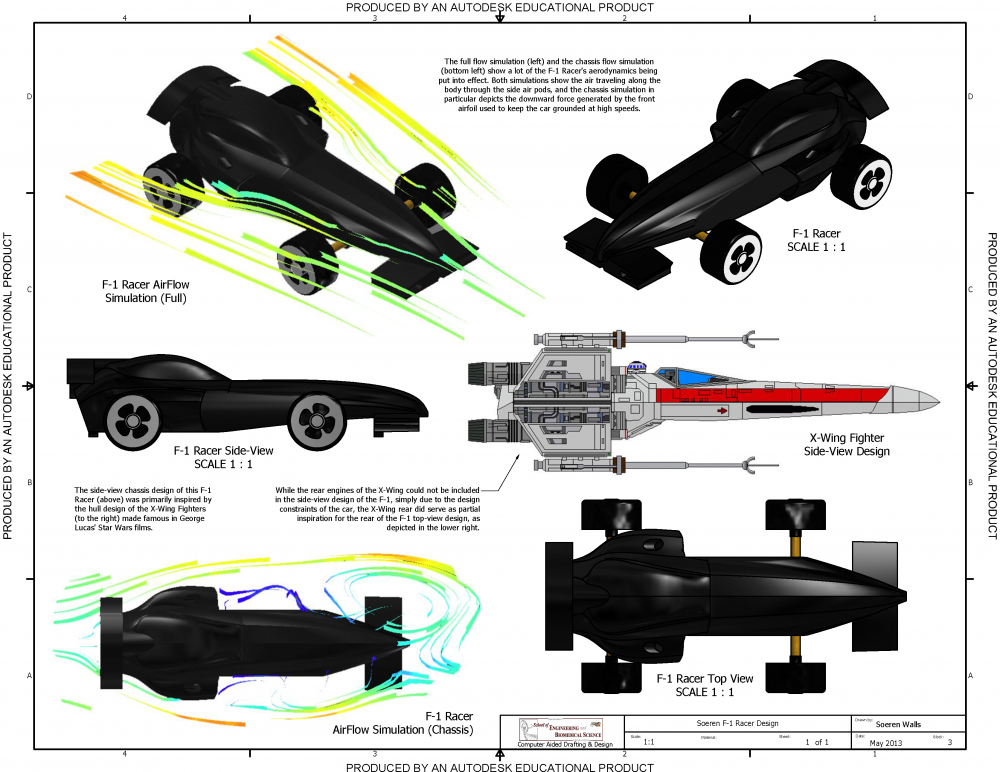

It’s my senior year at SEBS, and a couple months ago, I found myself in CADD 4, tasked with designing, 3D printing, and racing a CO2-powered car. But why settle for a generic racer when you can channel the spirit of George Lucas? The side-view chassis of my racer was inspired by the sleek profile of Formula 1 cars and the iconic hull of the X-Wing Fighter from Star Wars. (Sadly, no R2-D2 included.)

While the rear engines of the X-Wing couldn’t make the cut due to design constraints (and, let’s be honest, the laws of physics), the top-view of the car still pays homage to the starfighter’s unmistakable silhouette. If you squint, you might just hear John Williams’ score in the background.

Angle view of the 3D-printed X-Wing F1 Racer. Bottom view of the 3D-printed X-Wing F1 Racer.

From Inventor to Reality: The Design & Build

Armed with Autodesk Inventor and a healthy dose of caffeine, I set out to create a car that looked fast even when standing still. The process involved:

- Sketching the X-Wing-inspired side and top profiles

- Sculpting aerodynamic pods and a front airfoil to keep the car grounded at high speeds

- Running airflow simulations to visualize how air would travel along the body and through the side pods

- 3D printing the chassis and assembling the wheels, axles, and CO2 cartridge

Aerodynamics: May the Downforce Be With You

The full flow simulation and chassis flow simulation (see below) show the F1 Racer’s aerodynamics in action. Air travels smoothly along the body, with the side air pods channeling flow and the front airfoil generating much-needed downforce. (Because nothing ruins a race like your car taking flight.)

Schematic including airflow simulation for the X-Wing F1 Racer.

The Big Race: Not the Fastest, But a Finalist

Race day arrived, and my X-Wing F1 was ready for launch. While it wasn’t the fastest in the class, it did make it to the final tournament bracket (a small victory in itself). The car covered 5 feet in just 0.15 seconds. For the math nerds: that’s a blistering 33.3 feet per second, or about 22.7 mph. Not bad for a 3D-printed high school project!

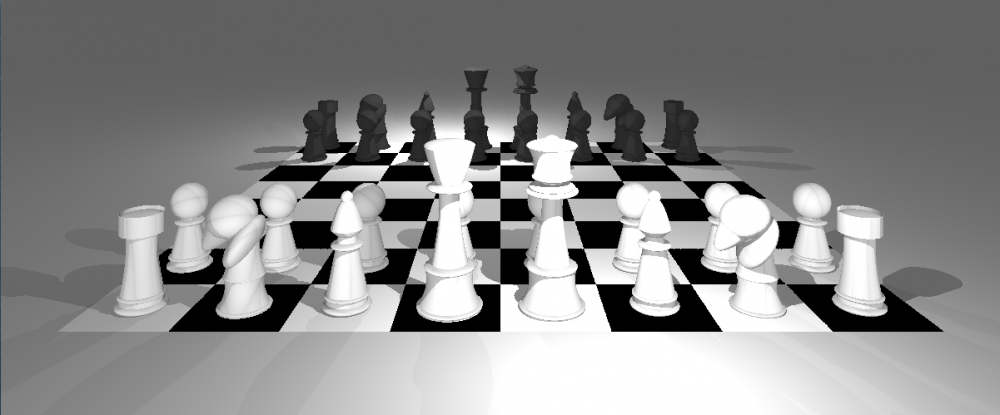

Gallery: The X-Wing F1 in All Its Glory

Reflections

This project was a blast (pun intended). It combined my love of Star Wars, engineering, and a little friendly competition. While I didn’t take home the gold, I did walk away with a deeper appreciation for CAD, 3D printing, and the magic of aerodynamic design. And hey, if anyone ever needs a CO2-powered escape vehicle for a galaxy far, far away, you know who to call.